Downhole Instrumentation Cables

4 mm (0.160”) Diameter. 150°C (302°F) Temperature Rated.

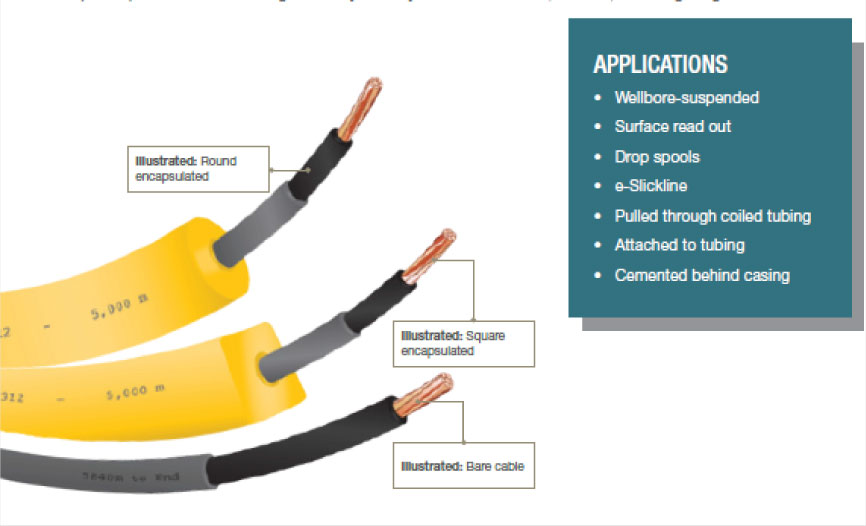

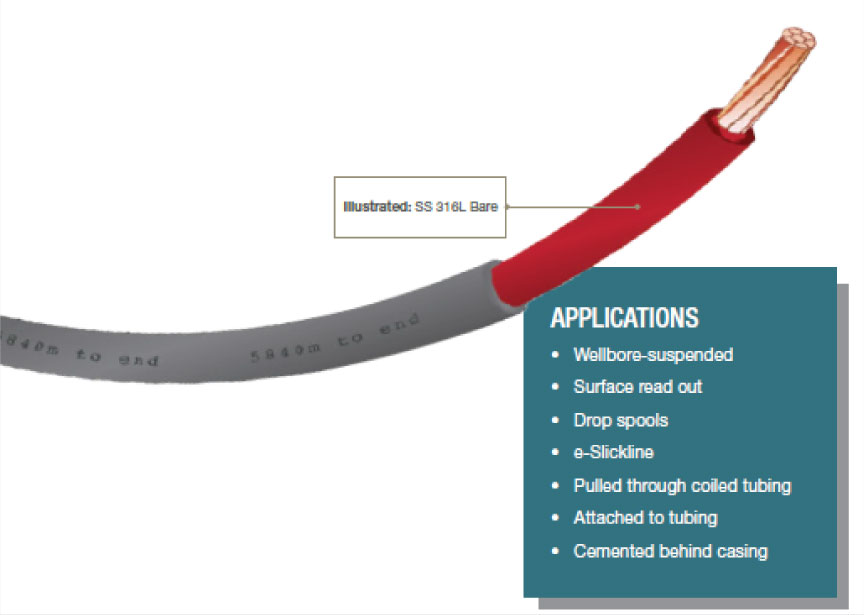

We offer various cold-formed, tungsten-inert-gas-welded stainless steel downhole instrumentation cables. Bare and encapsulated cables are marked with depth, manufacturing lot number, and other product information. Products can be manufactured to custom lengths and ship on heat-treated, certified wooden pallets and reels. Metal reels are also available.

PRODUCT SUMMARY

We are proudly that we meet or exceed the rigorous American Society for Testing and Materials (ASTM) A632 and ASTM E426 standards for stainless steel tubing. 4 mm (0.160”) downhole instrumentation cable (also known as tubular encapsulated cable [TEC] is the ideal combination of strength and flexibility. The 0.762 mm (0.030”) stainless steel wall thickness is stronger than most 6.35 mm (0.250”) TEC cables, which have wall thicknesses of 0.711 mm (0.028”) or 0.889 mm (0.035”). The 4 mm (0.160”) form is flexible enough to easily exit any standard wellhead, flowline, or casing wing valve.

4 mm (0.1575”) Diameter. 200°C (392°F) Temperature Rated.

We offer various cold-formed, tungsten-inert-gas-welded stainless steel downhole instrumentation cables. Bare and encapsulated cables are marked with depth, manufacturing lot number, and other product information. Our products can be manufactured to custom lengths and ship on heat-treated, certified wooden pallets and reels. Metal reels are also available.

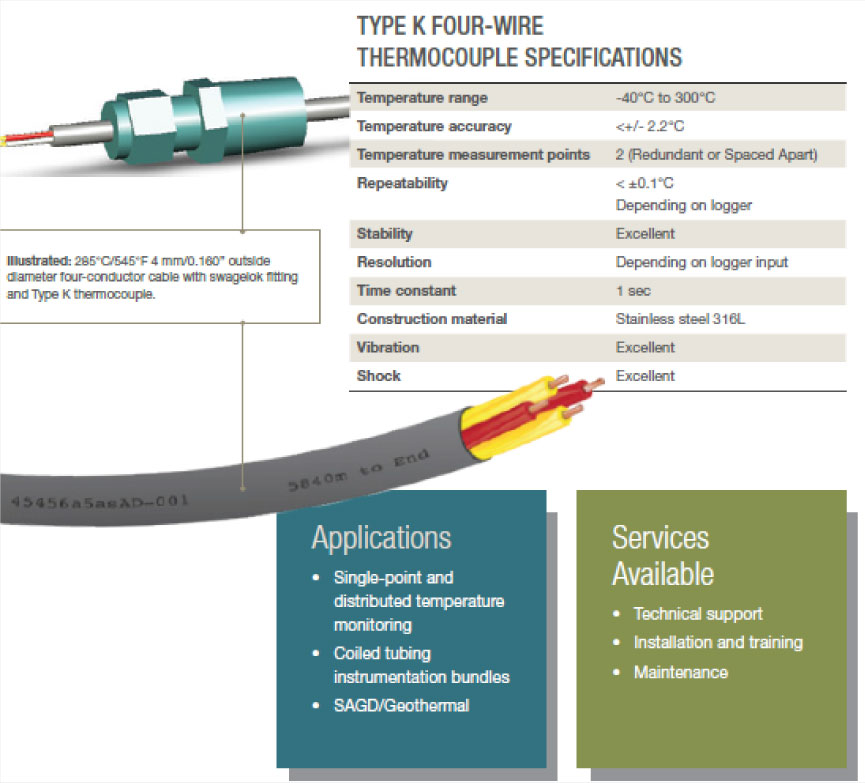

285°C/545°F Four-Conductor Thermocouple Downhole Instrumentation Cable

PRODUCT SUMMARY

Type K thermocouple sensors provide the most robust and reliable solution for temperature measurement in high-temperature reservoirs. Compared to fiber optic solutions, thermocouples are more cost-effective—and they do not suffer the effect of hydrogen darkening.